In no segment of the German printing industry is the competitive pressure felt as much as in commercial printing. Since 2015, sales of the most important product groups in the commercial sector have declined by 3.8 per cent annually, while the number of businesses has “only” decreased by 2.6 per cent. Moreover, no business sector in the printing industry is more affected by the disruptive business models of online printers than traditional commercial printers.

This blog post deals with the opportunities and risks of the commercial market and provides helpful, strategic assistance for future development. This article shows: the more digitally a printing company’s entire value chain is mapped, the more profitably it can operate. The degree of digitalisation goes hand in hand with a sustainable improvement in operational excellence and competitiveness.

The commercial market in Germany

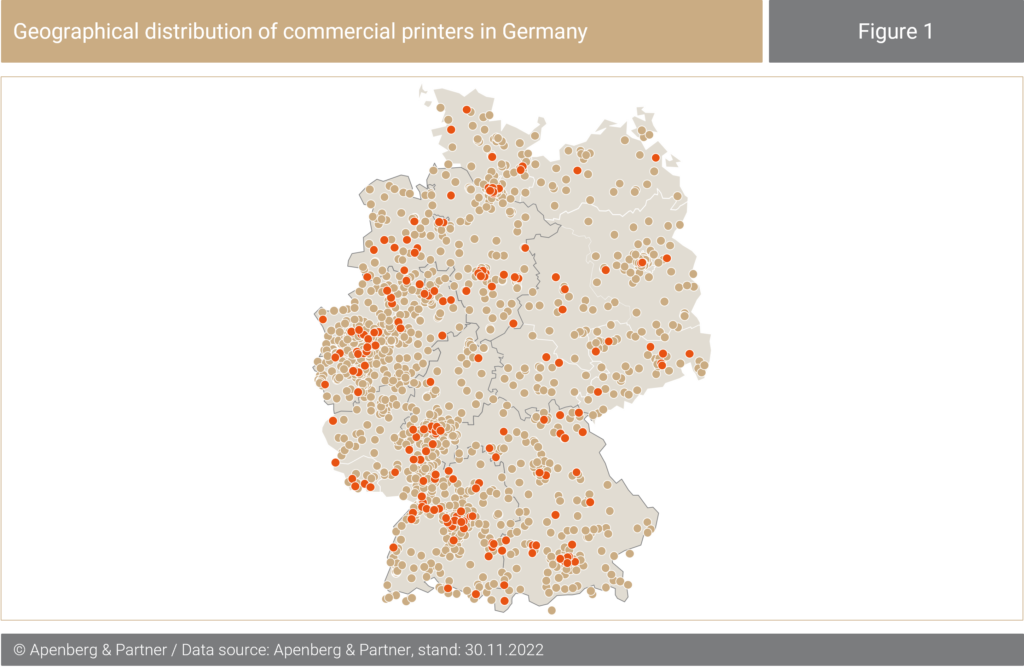

In Germany, Apenberg & Partner counts about 2,307 commercial printers. 83 percent of them employlessthan20people.Since2015,about400commercialprintershaveleft the market.

According to estimates by A&P, commercial printers, with their most important product groups, have achieved a turnover of 5.3 billion euros in 2021. However, the volume of the commercial market has shrunk by 3.8 per cent annually since 2015. The number of companies we consider the core of commercial printers has also declined by 2.6 per cent in the comparison period.

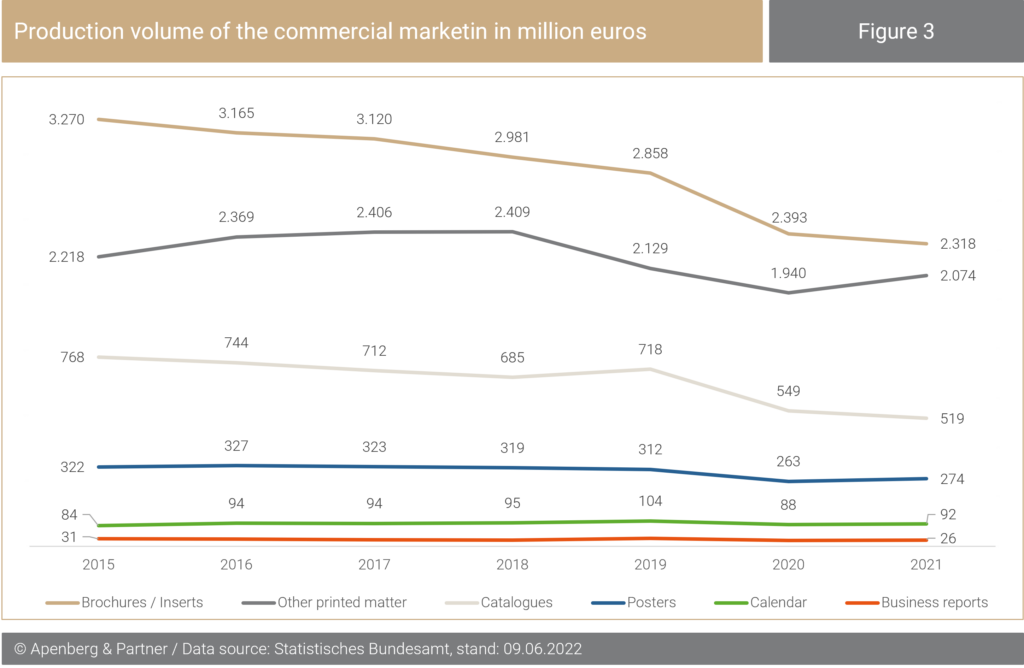

Turnover development of the product groups 2021

The most important product groups of commercial printers are “brochures/inserts” with a production turnover of 2.3 billion euros, and “other printed matter” with a turnover of 2.0 billion euros. The third-largest product group is “catalogues” with sales of 510 million euros. The remaining products “posters”, “calendars” and “annual reports” together still achieve 392 million euros.

„Operational Excellence (OPEX) – what are we actually talking about?

Operational Excellence (OPEX) describes the ability of a company to continuously optimise its processes and systems along the entire value chain. OPEX means aligning structures, processes and behaviours along the value chain to create a learning and continuously improving organisation that focuses on highly efficient implementation of customer requirements.

The “Digital Transformation” provides innovative printers with another powerful tool. It opens up previously undreamed-of possibilities on the way to an “Integrated Print Factory”.

A profitable printing company without “Digital Transformation” and “OPEX” is inconceivable

A commercial printer that completely forgoes digitally optimised production and communication processes will never be able to operate profitably again. The current competitive situation already makes this impossible. Against this backdrop, commercial printers in particular are called upon to review their business models and in most cases radically change them. The fact that some companies in the printing industry have already successfully gone down the transformation path should be sufficient motivation to compete with the best.

Using the example of German commercial printers, Apenberg & Partner has analysed the progress of the digital transformation. The following chart (Figure 4) illustrates the status of the digital transformation of commercial printers in Germany. The analysis is based on data from 2021 and includes 392 commercial printers that employed more than 20 people.

The survey concludes that only 15 per cent of commercial printers (A+B) digitally map significant areas of their value chain. 30 per cent of commercial printers (C) lull themselves into a sense of security despite insufficient digital processes because they still make good profits with their traditional businesses. The largest number of companies surveyed in this blog (D), largely forgo effective measures to optimise their operations through digital processes.

Commercial printers with a digital mindset (category: A)

A-companies (20 out of 392 companies) are the beneficiaries of the digital transformation. They have extensively digitalised their value chain, are transparent and use the daily data to continuously improve their processes. They achieve “operational excellence” in most areas of their value chain, are leaders in resource optimisation and are thus rightly considered among the most sustainable companies in commercial printing.

It is always impressive to experience that the people in these companies have a digital mindset that only knows solutions and no problems.

Commercial printers who have done their homework (Category: B)

The B-companies (approx. 39 of 392 companies) have done their homework. They have used the last two years to significantly streamline their production through digital processes. They have set out on the path to a transparent “Integrated Print Factory” and thus created the conditions for profitable growth. Many of the companies we know have understood how to tackle new things without neglecting their core business.

We earn money – Why should we change anything? (Category: C)

Convincing economically successful C-companies (approx. 118 companies) to change is considered a Champions leage task among consultants. Management in these companies shows little willingness to leave their traditional success factors (comfort zone). Often it remains unrecognised that they have lost touch with the best in their sector.

Crisis signals – What are these companies still waiting for? (Category: D)

These D-companies (approx. 216 companies) are clear restructuring cases. They have invested virtually no resources in digitally optimised production processes and have lost touch with the best competitors in their sector. The core business has not been growing for a long time and the loss of market share is inevitable. The sooner companies start restructuring, the better their chances of emerging stronger from a crisis. Visit our website “Restructuring & Crisis“ for more information on this topic.

Tips on the way to a sustainable commercial print shop

- Make a strategic decision! Decide to become one of the best in the industry within the next five years.

- Start the digital transformation without neglecting the core business. 70 percent of the resources are dedicated to the optimisation of the core business, 20 percent deal with innovations and improvements that provide benefits close to the core business. The remaining 10 percent are invested in truly new things.

- The future is dynamic. Develop your agile organisation today so that you can continue to move flexibly, quickly and precisely in the market tomorrow.

- The general mood of crisis is not a good advisor for change. People are burdened with their own worries and have less and less energy for their companies. Take employees with you on the “journey”. Get them excited about the future project of a sustainable print shop.

- Get external support. No company has the appropriate know-how and the necessary resources to manage a digital transformation “alone”. Give your project the importance it deserves.

Conclusion:

The success of a commercial printing company is decisively determined by the degree of digitalisation of its value creation processes. Digital transformation creates the conditions for further optimisation of “Operational Excellence (OPEX)” and ensures sustainable profitable growth.

More articles on this topic: